YOU’LL NEVER RUN OUT OF

CRITICAL PARTS AGAIN

TEAM OF FORE RUNNER

AM-SPECIALISTS AT YOUR SERVICE!

This is what we are committed to:

We want to ensure the optimized parts production for process-, manufacturing- and defense-industry customers with extensive AM-expertise – quickly, reliably, sustainably and cost-effectively. No matter what happens.

Is your part production already optimized?

WE’RE ON A MISSION!

Our innovation and concepting expertise combined with cost-effective ADDITIVE MANUFACTURING (AM) minimizes material needs, waste and emissions.

We are responsible, fast and sustainable.

You’ll never run out of optimized parts again

3D PRINTING of polymers and metals

We have a long experience in industrial 3D printing of polymers and a wide range of metals.

High-quality plastic products and components in a variety of plastic grades. Our experience in 3D printing, the latest production technologies and a wide range of materials at your disposal, we can implement your project from prototypes to support product development and mass production.

Years of experience in industrial 3D printing and the know-how accumulated through challenging projects are at your disposal. We implement all types of projects from prototypes and product development to full serial production.

You’ll never run out of

MASS PRODUCTION parts again

3D PRINTING of polymers and metals

We have a long experience in industrial 3D printing of polymers and a wide range of metals.

High-quality plastic products and components in a variety of plastic grades. Our experience in 3D printing, the latest production technologies and a wide range of materials at your disposal, we can implement your project from prototypes to support product development and mass production.

Years of experience in industrial 3D printing and the know-how accumulated through challenging projects are at your disposal. We implement all types of projects from prototypes and product development to full serial production.

You’ll never run out of

MASS PRODUCTION parts again

FROM NEED TO PRODUCTION

IN DAYS

ADDITIVE MANUFACTURING (AM) offers the opportunity to think about product design and production in new ways.

The greatest benefits are achieved when parts are designed and optimized for AM.

We’re happy to help you to find your optimized path.

RESPONSIBLE AND SUSTAINABLE

There is practically no waste in AM technology! Almost all excess powder is recycled and used in next production batch.

Recyclability, locally produced components, responsible energy thinking, zero inventory a.k.a no need for storage etc.

Valuable aspects for all our customers!

You’ll never run out of sustainable parts again

PARTS ON-DEMAND – FACTORY AS A SERVICE (FaaS)

Can your operation be interrupted due to a lack of parts or

components?

3D printing a.k.a AM is the solution. We can provide you with an AM plant that ensures parts availability and process continuity regardless of order volumes. Low or high.

3DStep's component services and digital spare parts ensure the functionality of your production. You maximise process uptime, minimise unnecessary downtime and create reliability. All backed by advanced product design and production planning.

You’ll never run out of

on-demand parts again

CUSTOMER BENEFITS

PARTS ON-DEMAND

Fast, optimized & secure production

ZERO INVENTORY

There is no need for inventory anymore!

SUSTAINABLE

Circular economy as it’s best

COST-EFFECTIVENESS

Material savings & recycling

FROM NEED TO PRODUCTION IN DAYS

Your situation sets the schedule

DIGITAL LIBRARY

And you are immeadately ready for production

FAST!

LET’S GET TOGETHER

You can book a free survey. A 3D mapping to find the potential of 3D printing in your company. Based on the mapping, products and activities can be further designed with clear insights into improved or new products, tools or spare parts.

3DLOIKKA online workshop produces an amazing amount of concrete results in 2 hours: ideas, concepts and design.

Free of charge.

JUMP IN!

some of our clients

CASE STORIES

3D printing as a problem solver for hundreds of companies and an enabler of innovations since 2012.

OPTOFIDELITY - POLYMER

MECHANICS WITH AGILE 3D PRINTING

The challenge for OptoFidelity was the large

number of plastic mechanical parts and the

variability of customers. The plastic mechanics were mainly produced by machining...

SENOP VALUES AGILITY, DURABILITY

AND DESIGN COLLABORATION IN 3D

PRINTING

Senop Communications ordered its first 3D

printed product from 3DStep in 2020 when the

company realised that the precise requirements

of a particular metal enclosure were difficult to

meet using traditional manufacturing methods...

MEDICAL APPLICATIONS - A CANCER PATIENT

HAS A NEW FEMUR BUILT

USING 3D PRINTS

3D printing also offers great opportunities for

medical applications. One heart-warming case

study involves a young patient with a malignant

tumour in the femoral stem. The tumour could

be removed by saving the patient's own...

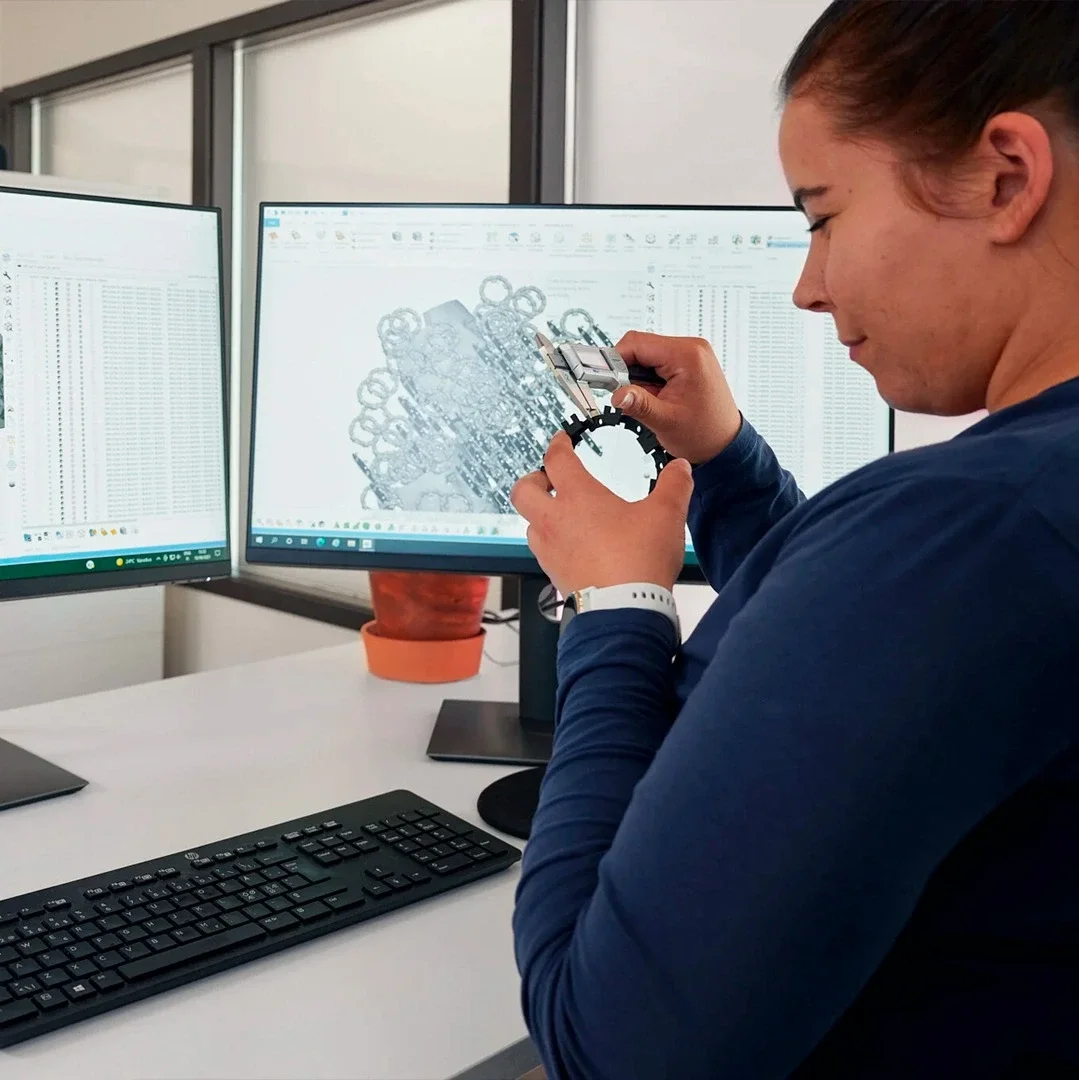

FROM IDEA TO A FINAL PRODUCT

INNOVATION AND CONCEPTING

DESIGN

MANUFACTURING

POST PROCESSING AND ASSEMBLY

You’ll never run out of PERFECT parts again

IF THE WORST HAPPENS!

Since the components are ready in a ready-made library, we can start production in minutes.

The digital library ensures the fastest possible start of production in the near future.

So if the worst happens, an emergency strikes big time, there is no need to panic, press the button below and we’re on it.

You’ll never run out of INSTANT parts again

CERTIFIED PROCESSES / ISO9001 & ISO14001

At 3DStep Oy, quality is at the heart of everything we do. Our certified quality processes ensure that our operations meet the highest standards from design and production to delivery. We invest in customer service, quality control and product testing at external testing facilities to ensure that the results meet our customers' requirements.

We are constantly improving our production automation. Automation reduces human error and increases the reliability of the production process.

3DStep has validated its own processes and we have validated data on the material properties produced by our processes.